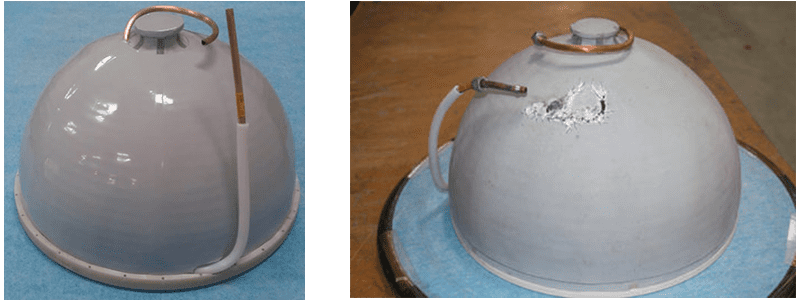

Custom coils, as the primary supplier to the OEM, provide end-user repair and refurbishment services for the HDP family of dome assemblies. Through multiple product maintenance cycles and extended process use, the components which make up the original assembly erode. Examples of component breakdown include water line leaks in the rf coil and cooling cap, breakdown of the outer silicone elastomer, electrical arcing of the rf coil, and scratches on the sealed surface of the ceramic dome.

The refurbishing process begins with stripping the ceramic dome of all components and sending it out to be reconditioned. Excess deposition on the inner surface of the ceramic is removed and the surface condition is restored to original surface roughness. The sealed surface is relapped and tested to ensure no leaks under a vacuum.

The ceramic dome is cleaned and returned to custom coils to be reassembled to original specification with all new components, and then sent out for final cleaning. Our bell jar refurbishing services have enabled end-users to extend the life of their original tool investment and achieve a higher rate of return.